Ultimate Guide to Finding the Best Used Machine Tools for Your Business Needs

In today’s competitive manufacturing landscape, the use of "Used Machine Tools" has become a pivotal strategy for businesses looking to optimize costs and enhance productivity. According to a report by MarketsandMarkets, the global machine tool market is projected to reach USD 88.6 billion by 2025, with the used segment gaining significant traction as industries seek affordable yet high-quality equipment. Companies are increasingly aware that acquiring used machinery not only reduces capital expenditure but also contributes to sustainable practices by extending the lifecycle of existing tools. However, selecting the right used machine tools requires careful consideration of detailed technical specifications to ensure they meet specific business needs. This ultimate guide aims to provide essential insights into evaluating used machine tools, enabling businesses to make informed decisions that align with their operational goals and enhance overall efficiency.

Understanding Import and Export Certifications for Used Machine Tools

When considering the acquisition of used machine tools, understanding import and export certifications is crucial for businesses looking to enhance their operational efficiency. The International Organization for Standardization (ISO) provides specific certifications that ensure used machinery meets global safety and quality standards. According to a recent report by the Market Research Future, the used machinery market is projected to grow at a CAGR of 5.8% from 2021 to 2027, highlighting the increasing demand for certified machinery that can contribute to sustainable manufacturing practices.

Businesses must navigate various regulatory landscapes when importing or exporting used machine tools. For instance, the U.S. Customs and Border Protection (CBP) outlines that machinery may be subject to additional inspections if they originate from countries with lax environmental regulations. Moreover, the compliance with the Machinery Directive (2006/42/EC) in the EU mandates that imported used machines are thoroughly inspected and certified to ensure they do not pose safety risks. This layer of certification not only safeguards the buyer's investment but also supports compliance with environmental standards, ultimately aligning with the growing emphasis on sustainability across the manufacturing sector.

Ultimate Guide to Finding the Best Used Machine Tools for Your Business Needs - Understanding Import and Export Certifications for Used Machine Tools

| Tool Type | Condition | Certification Status | Import/Export Compliance | Price Range ($) |

|---|---|---|---|---|

| CNC Lathe | Used | Certified | Compliant | 5,000 - 15,000 |

| Milling Machine | Good | Not Certified | Pending Verification | 3,000 - 8,000 |

| Hydraulic Press | Like New | Certified | Compliant | 10,000 - 25,000 |

| Band Saw | Fair | Not Certified | Non-Compliant | 1,000 - 3,000 |

| Surface Grinder | Used | Certified | Compliant | 4,000 - 12,000 |

Key Digital Tools to Enhance Your Used Machine Tool Selection Process

When it comes to selecting the best used machine tools for your business, integrating key digital tools can significantly enhance your decision-making process. As industries increasingly adopt artificial intelligence (AI) and predictive analytics, businesses can utilize these technologies to filter options more effectively. For instance, visual search tools powered by computer vision can allow operators to quickly compare specifications and prices of used machinery, streamlining the selection process.

Moreover, employing natural language processing (NLP) can assist buyers in sifting through customer reviews and technical documentation. This allows for a more informed choice by understanding not only the condition of the machinery but also the reliability of the seller. Digital twins technology can further simulate the machine's performance, helping you to anticipate how a particular tool will integrate within your operations. With these innovative tools at your disposal, finding the right used machine tools can be both efficient and tailored to meet the specific needs of your business.

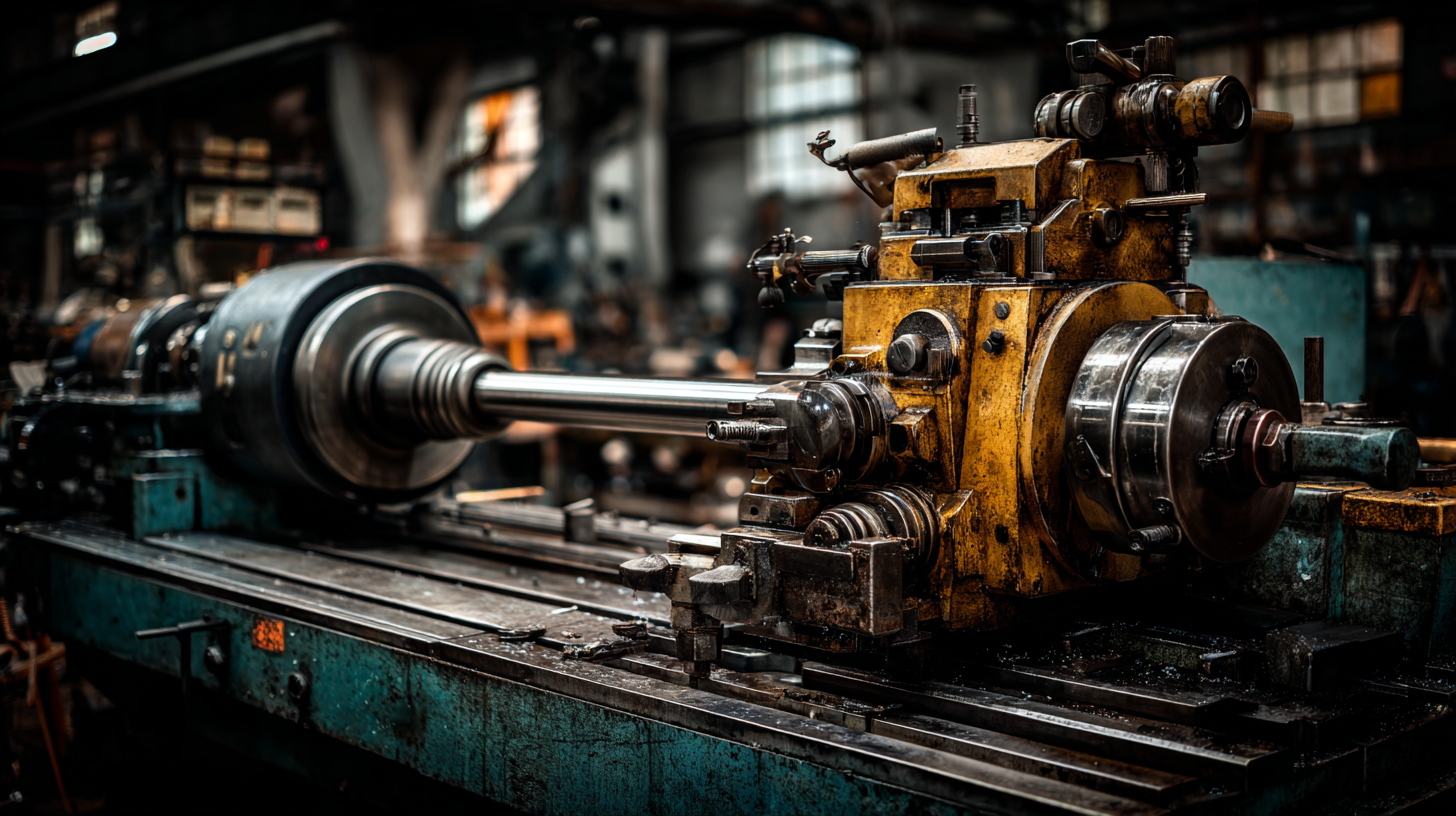

Top Types of Used Machine Tools: How to Choose the Right Fit for Your Business

When selecting the right used machine tools for your business, understanding the top types available and their specific applications is crucial. According to a recent report from the Association for Manufacturing Technology (AMT), the demand for used CNC machines has surged by 15% over the last year, highlighting their integral role in maintaining cost-efficiency while enhancing precision in production. Key types include CNC lathes, milling machines, and grinders, each offering unique capabilities that align with diverse manufacturing processes.

CNC lathes, for instance, are essential for businesses focused on producing cylindrical parts efficiently. Their advanced programming capabilities enable high-speed machining, which is critical for meeting tight production deadlines. Conversely, milling machines cater to a broader range of applications, including drilling and engraving, making them versatile assets in any workshop. Furthermore, the market for used machinery is projected to grow at a CAGR of 7.5% over the next five years, as noted in a report by Research and Markets. This trend encourages businesses to make informed decisions when investing in used tools, ensuring they select models that not only fit their operational needs but also provide a solid return on investment.

CNC lathes, for instance, are essential for businesses focused on producing cylindrical parts efficiently. Their advanced programming capabilities enable high-speed machining, which is critical for meeting tight production deadlines. Conversely, milling machines cater to a broader range of applications, including drilling and engraving, making them versatile assets in any workshop. Furthermore, the market for used machinery is projected to grow at a CAGR of 7.5% over the next five years, as noted in a report by Research and Markets. This trend encourages businesses to make informed decisions when investing in used tools, ensuring they select models that not only fit their operational needs but also provide a solid return on investment.

Critical Factors to Consider When Evaluating the Condition of Used Machinery

When evaluating the condition of used machinery, several critical factors must be taken into account to ensure you make a sound investment for your business. First and foremost, it’s essential to assess the machine's overall appearance and functionality. Look for signs of wear and tear, such as rust, cracks, or misalignment. A thorough inspection of the machine's components will also reveal whether maintenance has been performed regularly and if any replacements are needed. Asking the seller for detailed maintenance records can provide insights into the machine's history and reliability.

Another important factor to consider is the availability of replacement parts. Older machines might be more affordable, but if parts are hard to come by, they could become a significant liability in the long run. Inquire about the machine's compatibility with modern technology, as this can also affect future upgrades and efficiency. Finally, consider the machine's operational capabilities, such as speed, precision, and versatility, to ensure it meets your production needs. By focusing on these critical aspects, you can make an informed decision that aligns with your business objectives.

Navigating the Market: Best Practices for Buying Used Machine Tools with Confidence

When navigating the market for used machine tools, it’s crucial to adopt a strategic approach, much like the evolving dynamics seen in the used car market. As inventory shortages gradually stabilize, buyers need to adapt their sourcing strategies. This shift highlights the importance of thorough research and understanding market trends, such as the specific demands within your industry and the average pricing of used equipment. By doing so, you can make informed choices that align with your business needs.

Additionally, as consumer expectations rise, there is a strong emphasis on quality and durability over cost. This trend underscores the critical step of vetting potential suppliers and assessing the condition of machine tools before making a purchase. Implementing practices like requesting detailed machine histories, evaluating performance metrics, and conducting inspections can help ensure you select the best tools available. Emphasizing these best practices will not only build your confidence in buying used machine tools but also safeguard your investment for long-term success.