Comprehensive Guide to Different Types of CNC Machining Centers and Their Applications

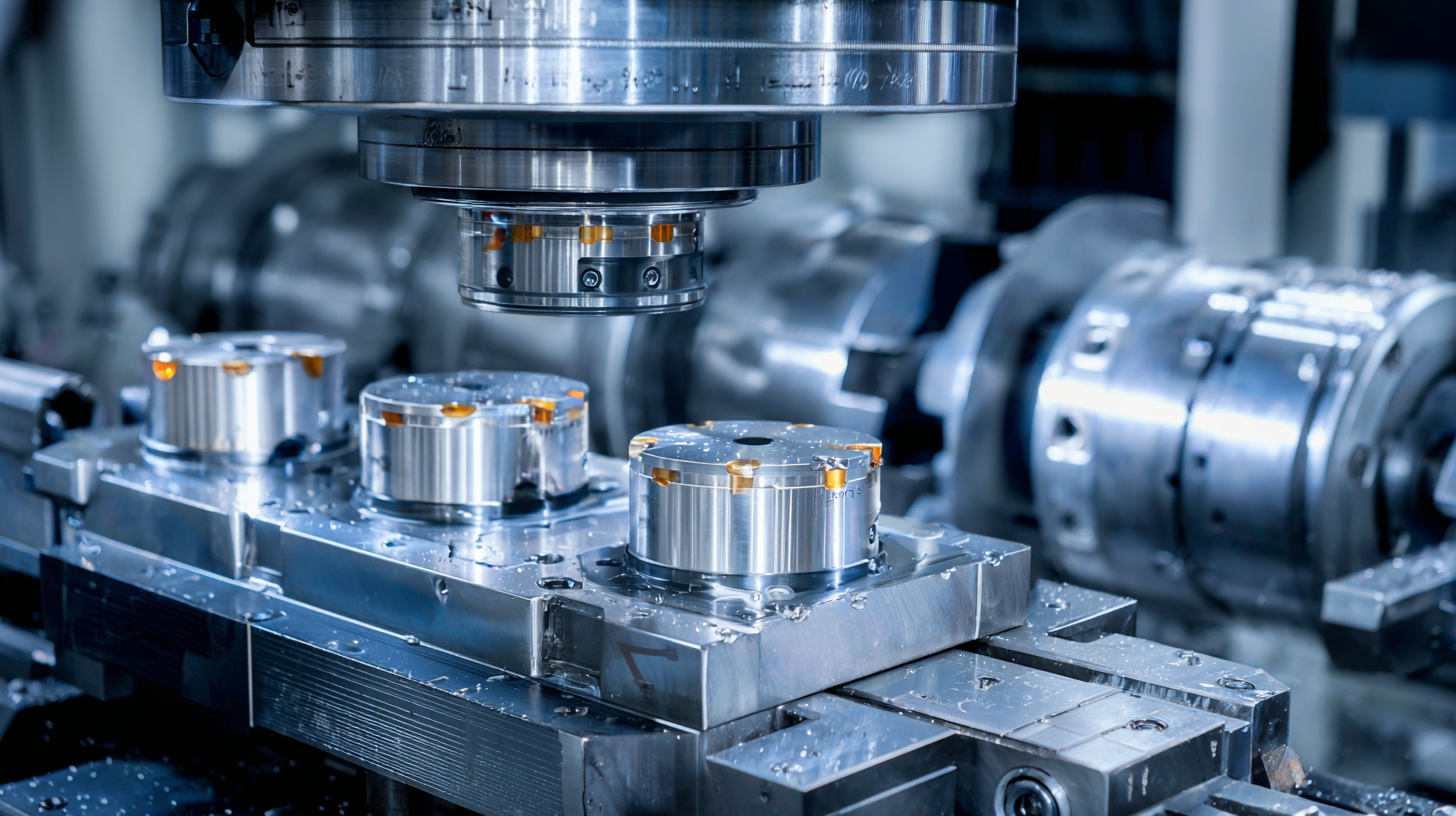

In today's fast-paced manufacturing landscape, understanding the various types of CNC Machining Centers and their specific applications is crucial for businesses looking to enhance their production capabilities. CNC Machining Centers are sophisticated machines that automate the machining processes, offering precision and efficiency that traditional methods struggle to match. From milling and drilling to turning and grinding, each type of CNC Machining Center serves distinct purposes, catering to diverse industries ranging from aerospace to automotive. This comprehensive guide will explore the different types of CNC Machining Centers, highlighting their unique features, advantages, and the reasons why choosing the right type is essential for optimizing workflows and achieving quality outputs. Whether you are a seasoned engineer or a newcomer to the manufacturing realm, gaining insights into these advanced machines will empower you to make informed decisions that align with your production goals.

Overview of CNC Machining Centers: Types and Technical Specifications

CNC (Computer Numerical Control) machining centers represent a crucial segment of the manufacturing industry, known for their versatility and precision. These advanced machines facilitate various machining processes, including milling, drilling, and turning, through programmable automation. The primary types of CNC machining centers include vertical machining centers (VMC), horizontal machining centers (HMC), and multi-axis machining centers, each designed to cater to specific manufacturing needs. VMCs are ideal for smaller parts and complex geometries, while HMCs excel in high-volume production with greater automation features.

CNC (Computer Numerical Control) machining centers represent a crucial segment of the manufacturing industry, known for their versatility and precision. These advanced machines facilitate various machining processes, including milling, drilling, and turning, through programmable automation. The primary types of CNC machining centers include vertical machining centers (VMC), horizontal machining centers (HMC), and multi-axis machining centers, each designed to cater to specific manufacturing needs. VMCs are ideal for smaller parts and complex geometries, while HMCs excel in high-volume production with greater automation features.

The technical specifications of these machining centers vary significantly based on their intended applications. Factors such as spindle speed, tool changing capabilities, and axis movement define their operational efficiency. For instance, a 5-axis machining center can handle intricate designs with ease, whereas a 3-axis machine might be more suitable for simpler tasks. As industries continuously evolve, the demand for CNC machining centers is projected to rise sharply, reflecting a significant market growth trend. This growth highlights the importance of selecting the right type of CNC machine to optimize production processes and meet the varying demands of manufacturing sectors.

Key Applications of CNC Machining Centers Across Various Industries

CNC machining centers have become integral to a multitude of industries, offering precision, efficiency, and versatility. These advanced machines excel in various applications, from automotive manufacturing to aerospace components. In the automotive sector, CNC machining centers are utilized for producing intricate parts with tight tolerances, enabling manufacturers to streamline processes and enhance performance. Their capability to handle multiple operations, such as milling, drilling, and turning in a single setup, significantly reduces production times and costs.

In addition to automotive, the aerospace industry reaps substantial benefits from CNC machining centers. Critical components such as turbine blades and structural elements require extreme precision and reliability, making CNC technology indispensable. Furthermore, the medical sector relies on CNC machining for producing specialized equipment and implants customized to patient-specific requirements. This adaptability across industries not only demonstrates the technology's broad applicability but also highlights the anticipated market growth, with a compound annual growth rate of 4.9% projected through 2032, reflecting increasing demand for precision engineering solutions globally.

Comprehensive Guide to Different Types of CNC Machining Centers and Their Applications

| Type of CNC Machining Center | Key Applications | Industries |

|---|---|---|

| 3-Axis CNC Milling Center | Machining complex shapes, drilling, and contour milling | Aerospace, Automotive, Electronics |

| 5-Axis CNC Machining Center | High precision parts, complex geometry machining | Medical, Aerospace, Defense |

| CNC Lathe | Turning operations, external and internal shaping | Manufacturing, Construction, Oil & Gas |

| CNC Router | Cutting, engraving, and shaping softer materials | Furniture, Sign making, Aerospace |

| CNC Waterjet Cutting Machine | Cutting hard materials without thermal distortion | Metalworking, Stone, Glass |

2025 Technological Trends: Innovations Shaping CNC Machining Centers

The CNC machining industry is poised for transformative changes driven by technological innovations leading up to 2025. With a projected global market expansion from $101.2 billion in 2025 to $195.59 billion by 2032, at a compound annual growth rate (CAGR) of 9.9%, it's clear that CNC technology will continue to evolve rapidly. In China alone, the CNC machine market is expected to reach approximately 432.5 billion yuan by 2024, showcasing a steady growth trend.

One significant trend shaping the landscape of CNC machining centers is the integration of advanced technologies such as AI and machine learning. These innovations not only enhance operational efficiency but also improve the precision and adaptability of machining processes. As seen with five-axis machining centers, which represent the pinnacle of complexity and capability, manufacturers are increasingly adopting advanced methods to meet the diverse needs of various industries. Coupled with the burgeoning laser processing equipment sector, which has garnered substantial market support, the landscape for CNC machining is becoming more sophisticated, enabling a higher degree of automation and precision in manufacturing operations.

Comparative Benefits of Different CNC Machining Types for Manufacturing Efficiency

In today’s competitive manufacturing landscape, understanding the comparative benefits of different types of CNC machining centers is crucial for optimizing efficiency.

CNC milling machines, lathes, and drilling centers each offer unique advantages depending on the specific demands of a project. For instance, CNC milling provides precision for complex geometries, making it ideal for intricate components, while CNC lathes excel at creating symmetrical parts with a high degree of accuracy.

Additionally, the growth of additive manufacturing, particularly in metal 3D printing, presents a new frontier in machining applications. This technology can significantly reduce material waste and offer diverse design possibilities, which traditional machining methods cannot achieve.

Manufacturers are increasingly evaluating the cost-benefit dynamics of CNC machines versus 3D printing to enhance productivity and streamline processes. By leveraging the strengths of various CNC machining types, businesses can better align their operations with modern manufacturing demands, leading to improved overall efficiency.

Market Growth and Future Projections for CNC Machining Technologies

The CNC machining industry is poised for significant growth over the next decade, with projections indicating that the global market will expand from $101.22 billion in 2025 to an impressive $195.59 billion by 2032. This represents a robust compound annual growth rate (CAGR) of 9.9%, driven by increasing technological advancements and the rising demand for automation in manufacturing processes. The emphasis on innovation, particularly in CNC technologies, has led to the adoption of more sophisticated machinery, such as 5-axis CNC machining centers, which are anticipated to grow from a market value of $250 million in 2022 to $395 million by 2030, reflecting a steady CAGR of 6.0%.

In addition to CNC machining centers, the laser processing equipment market is also witnessing remarkable growth. Forecasts suggest an increase from $28.51 billion in 2025 to $64.39 billion in 2032, translating to an annual growth rate of 12.3%. Other segments, including metal processing equipment and linear motion products, are similarly experiencing an upward trend, emphasizing a broader industrial shift towards high-precision machining solutions. This growth can be attributed to the continuous evolution of production capabilities and the industry's focus on efficiency and quality, setting the stage for a dynamic future in CNC machining technologies.